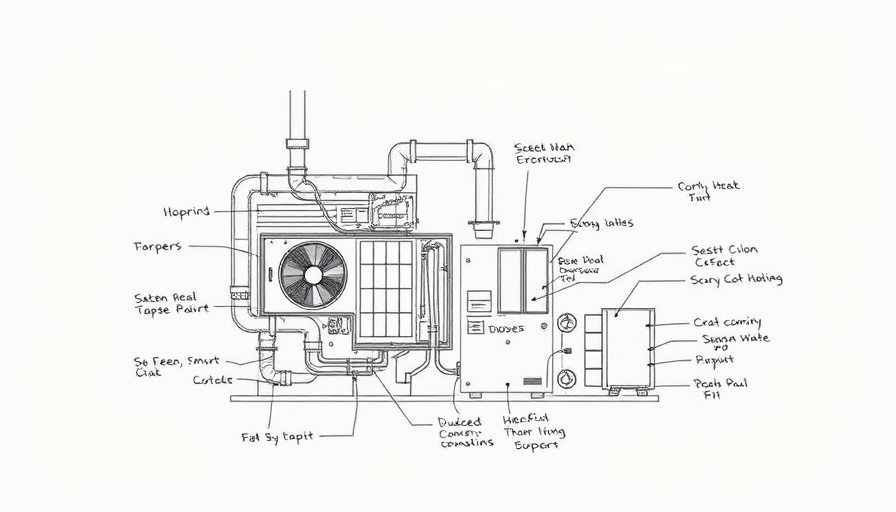

Understanding Static Pressure Loss in Ducted Heat Pump Systems

Ducted heat pump systems offer an efficient solution for maintaining comfortable indoor temperatures. However, one of the challenges faced when implementing these systems is understanding static pressure loss. Static pressure loss refers to the decrease in air pressure caused by friction and other resistive factors as air flows through the ductwork. This loss can significantly impact the efficiency and effectiveness of heating and cooling operations.

The Role of Central Return Systems

Central return systems are essential for balancing airflow throughout a heating or cooling system. They improve air distribution and can minimize noise levels, providing a more comfortable living environment. However, these systems can contribute to static pressure loss if not correctly designed and installed. Ensuring that duct sizes, configurations, and return locations are optimized can greatly enhance overall performance.

Exploring Noise Reduction Techniques

Noise often arises from airflow turbulence within ducts, which can be particularly prominent when air returns are centrally located. Techniques to reduce this noise may include adjusting duct sizes or using sound-dampening materials. Additionally, strategically placing dampers can help minimize noise while maintaining effective air circulation. Addressing these noise issues can directly impact indoor air quality and comfort.

Measuring Static Pressure: Methods and Tools

Measuring static pressure is crucial for diagnosing system performance issues. Accurate readings can be obtained using a manometer connected to pressure taps in the ductwork. This process assists technicians in assessing pressure readings against manufacturer-recommended guidelines, allowing for any necessary adjustments to be made. Understanding how to measure and interpret static pressure is critical for optimizing heat pump performance.

The Importance of Insulation

Proper insulation plays a vital role in maintaining static pressure within ducted systems. Insulation minimizes temperature loss, improves energy efficiency, and reduces the chances of pressure imbalances caused by thermal expansion or contraction. It is essential for workers installing ducted heat pumps to apply insulation carefully, ensuring that all ducts are properly sealed and insulated to maintain system efficiency.

Expert Recommendations for Duct Design

Experts recommend considering a few key factors when designing a ducted heat pump system to minimize static pressure loss. These factors include the total length of duct runs, transitions from one size to another, and the use of smooth, gradual bends instead of sharp turns. Following these guidelines can enhance system performance and longevity, leading to lower energy consumption and costs.

Statistical Data on Efficiency Gains

Research indicates that systems with optimized duct design can achieve energy savings of up to 20%. By measuring and analyzing static pressure loss, HVAC professionals can tailor installations to maximize efficiency. Not only does this improve comfort and air quality, but it also leads to substantial cost savings on energy bills.

Conclusion: The Road Ahead

As advancements in technology continue to evolve, incorporating smart monitoring solutions into ducted heat pump systems will become increasingly important. These systems can offer real-time data on airflow and pressure levels, allowing for proactive maintenance and adjustments. Embracing these innovations can significantly enhance the efficiency and comfort provided by ducted heating and cooling solutions.

Add Row

Add Row  Add

Add

Add Row

Add Row  Add

Add

Write A Comment